NC-Hops: The variant CAD/CAM system for processing wood, plastic and aluminium

NC-Hops has variable macro technology and is ideally suited to programming complex components for your CNC machine quickly, easily and save.

NC-Hops is used in the following industries:

- furniture production

- interior fittings

- door production for leaf and frame

- staircase manufacturing

- window production

- facade construction

- ship interior outfitting and yacht building

- truck trailer and caravan production

- acoustic components

Advantages of programming with NC hops:

- quick and easy input in dialogue with EasySnap function

- create your own macros

- different views in 2D and 3D

- machine-independent programming

- many system macros, e.g. for text milling, free pockets

- programming of 5-axis machining operations

- flexible interface concept

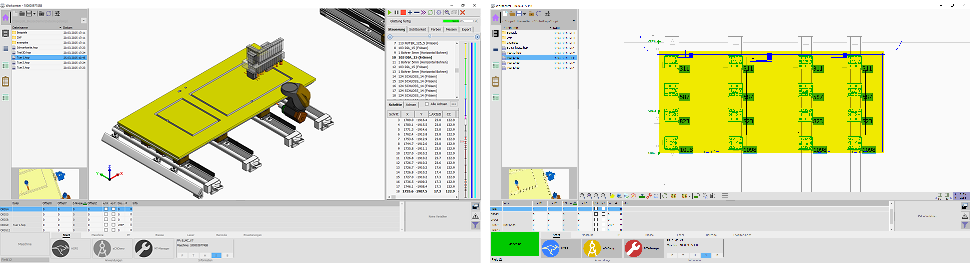

Workcenter

- convenient setup of workpieces

- automatic positioning of the suction cups and clamps

- integrated drilling and movement optimisation

- direct communication with the CNC machine

- simple shifting and turning of the workpieces on the machine table

- possibility of multiple assignment of workpieces

- automatic reclamping of window and door parts

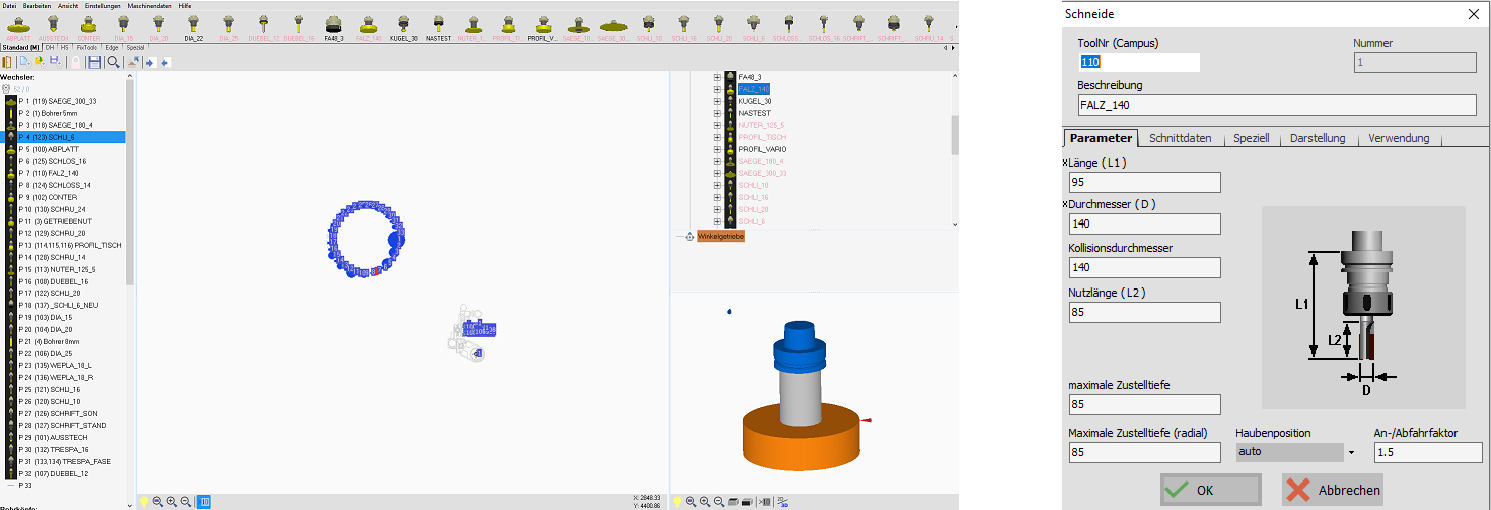

MT-Manager

- convenient creation of tools and machine details with graphical support

- simple dialogues with help graphics for defining the tool parameters

- graphic view of the drilling and milling units

- direct communication with the tool memory of the machine control unit

Machine simulation with material removal and collision control:

- visualisation of the machined material

- visualisation of Spannelemente

- display of profile tools

- integrated collision control

- zoom in on any details

- possibility to control the sequence of operations on the machine

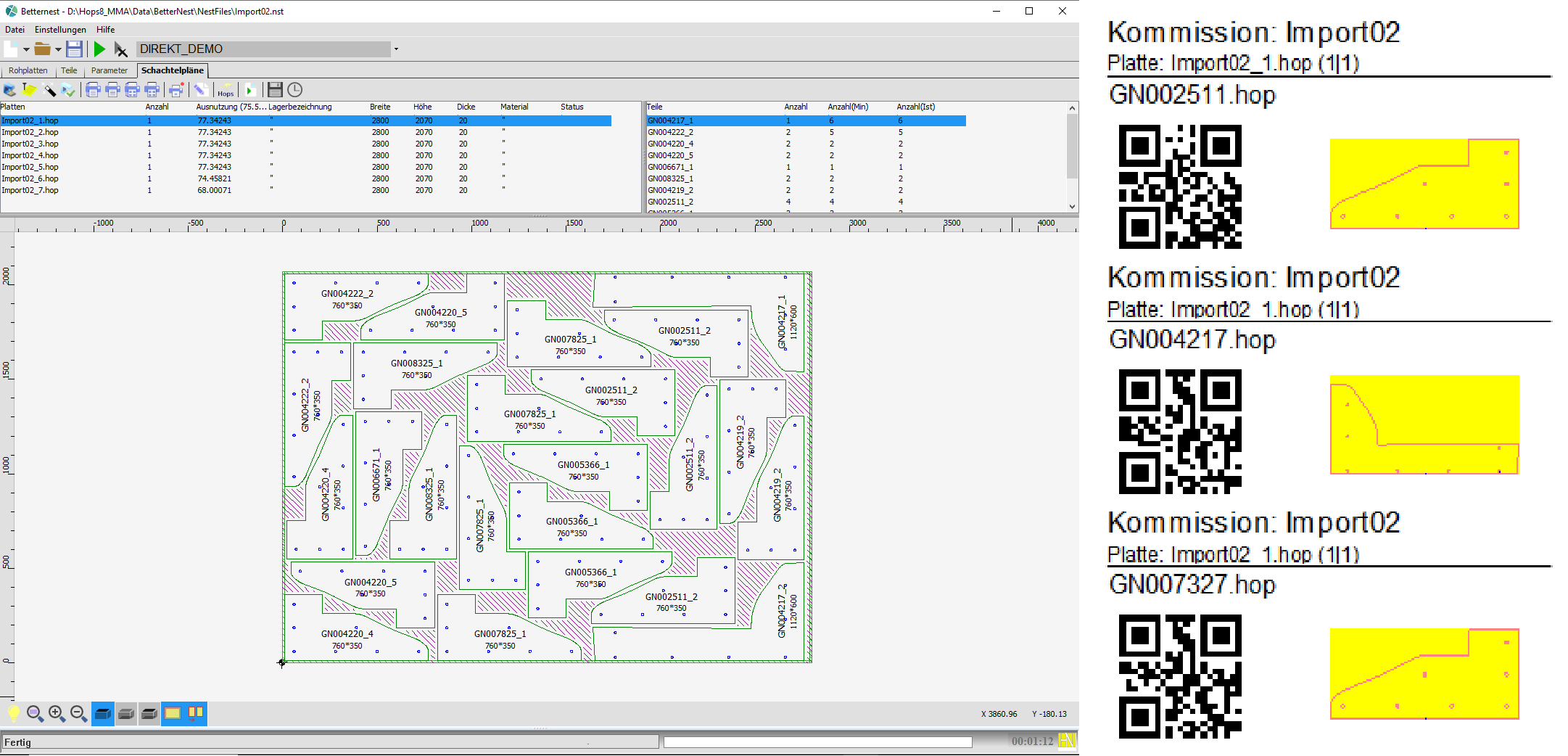

BetterNest

- material savings through optimisation

- labelling of all single parts

- communication with ERP systems and boards warehouse management

- importing parts lists

- stay-down strategy - avoidance of lead-in and lead-out movements across several components

- betterline strategy - single milling between 2 parts

- creatiion of bars

- residual part shredding

- machining on both sides possible

- clamex machining in the nest

- optimisation of the processing sequences for optimum use of the vacuum

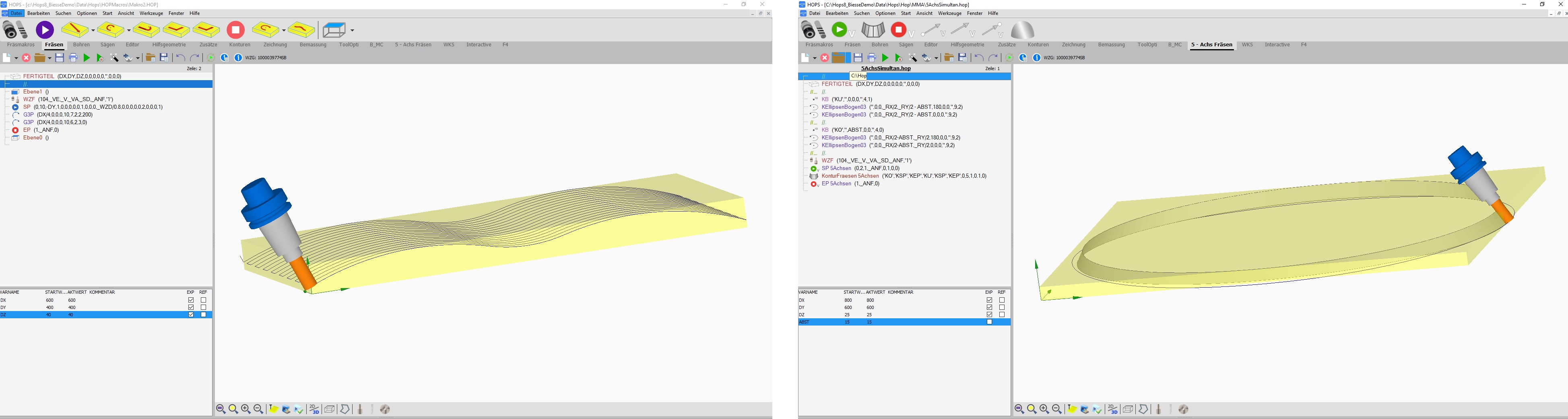

5-axis simultaneous

- milling of 3-dimensional contours with 5 axes

- constantly changing angular position of the tool to the milling contour

- very simple programming via head and foot contour

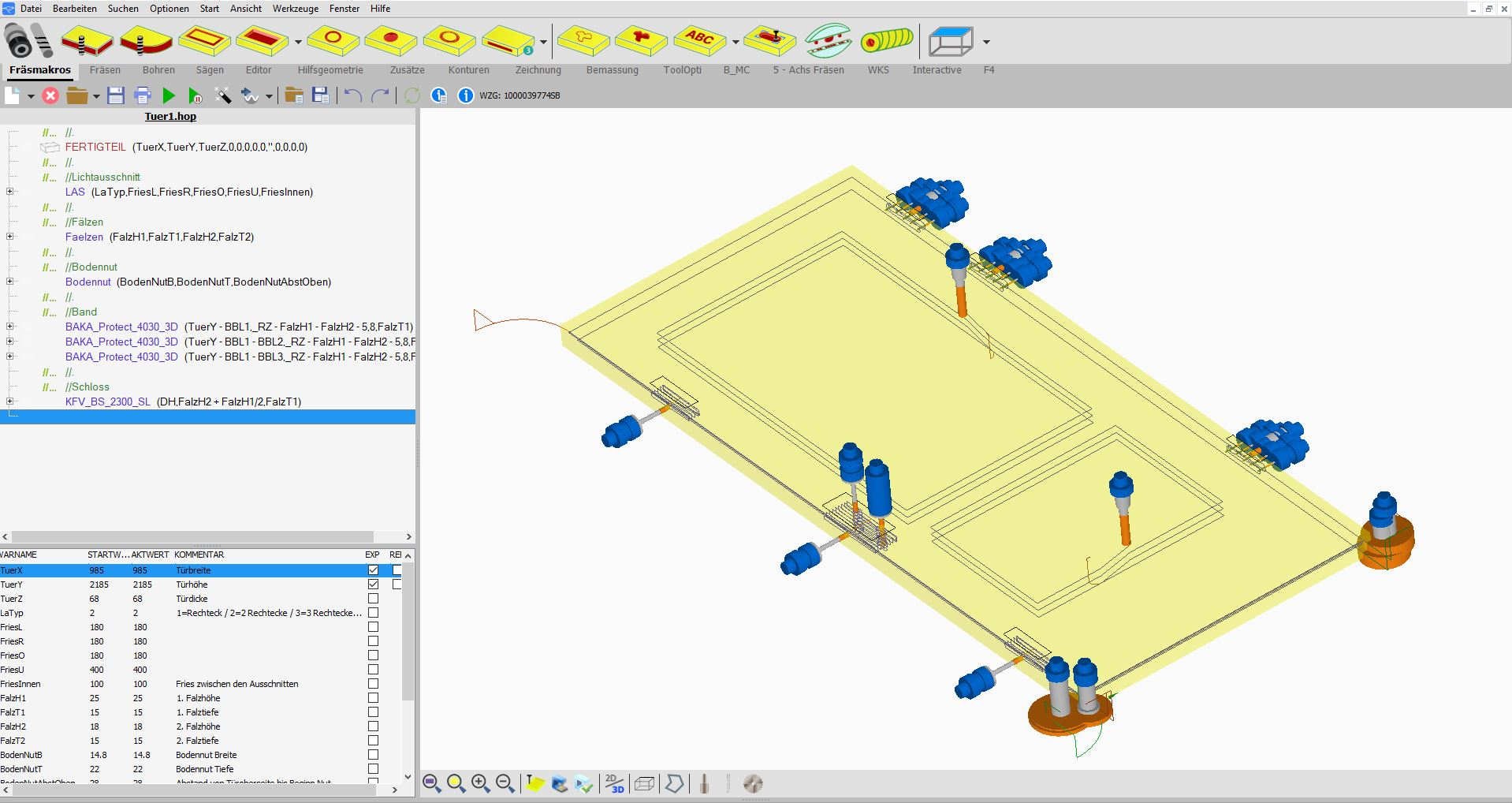

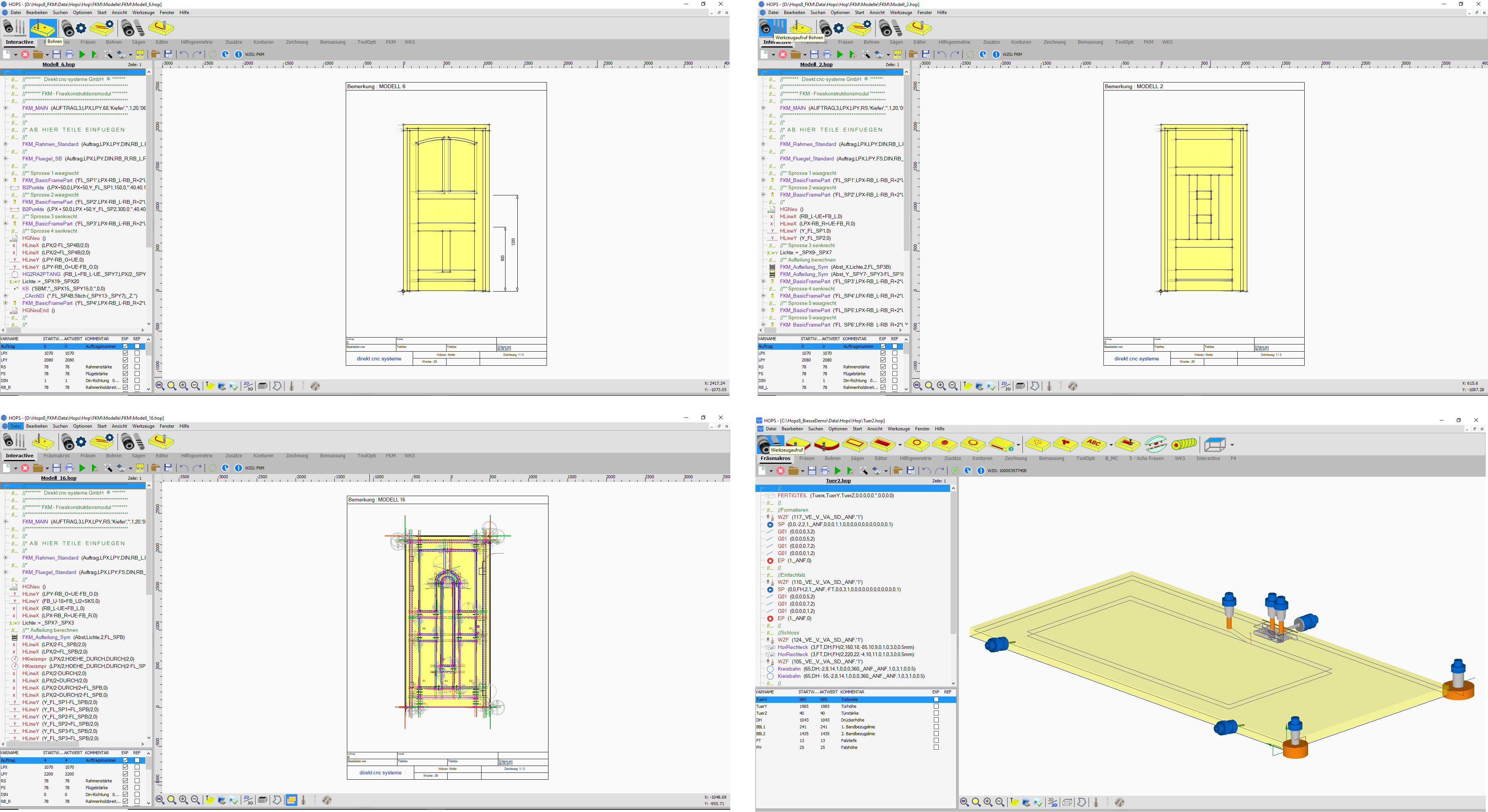

Door processing / Fenmatik / Fentura (FKM)

- simple programming of framed doors with automatic individual part output

- simple programming of room doors via predefined macros for fittings

- possibility to create your own door models

- parametric creation of your own door models including all posts and frame parts

- data transfer from window construction programmes

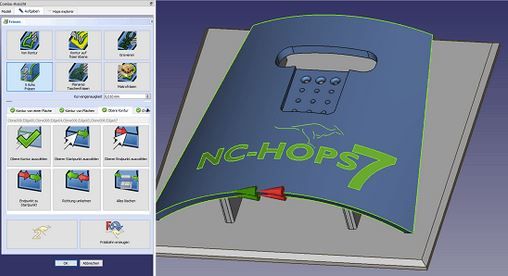

BetterCam

- BetterCam is the optimal interface between FreeCAD and NC-Hops

- simply define your NC machining operations on the 3D Solid

- many features are available for the realisation of your individual milling strategy

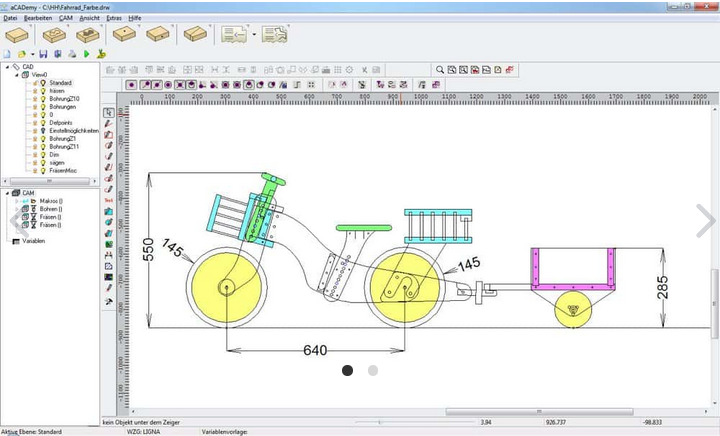

aCADemy

- convenient design options via CAD functions

- import option for DXF/DWG data

- extensive geometry functions such as polyline, spline, elliptical arc, etc.

- fast transfer of CAD data to NC hops